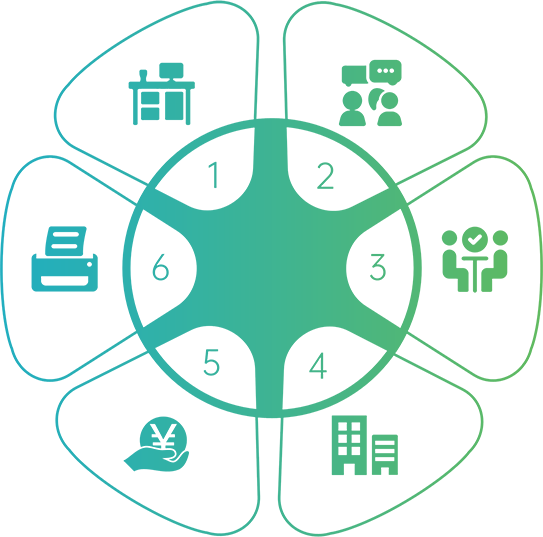

Environmentally Friendly Mulch Film Service

Fully biodegradable mulch film research-production-sales

Customize differentiated mulch film solutions based on regional climate-soil-crop complex models

Core Technology

Degradation rate customization: The formula can be adjusted based on different climatic zones (such as the South China with high temperature and high humidity and the Northeast China with low temperature and high dryness), achieving a "slow first, then fast" degradation curve - maintaining functions of film within 60 days after transplanting, and then accelerating degradation afterwards to prevent residual film from harming the next crop.

PBAT modification technology: By blending the raw materials (PBAT/PLA), (tear resistance > 15MPa) and ductility (elongation at break > 500%) of the film are improved to solve the problem that traditional biodegradable films can be easily broken.

Degradation Time Can Be Regulated

The induction period can be adjusted from 30-150 days to better meet the degradation needs of different crops and regions.

Adjustable Thickness

The thickness of the plastic film can be customized and adjusted according to different regions and crops.

Increase Production and Income

On the one hand, it can improve the soil, and on the other hand, degrading plastic film has a significant yield increasing effect on some crops.

Fully Biodegradable

After crop harvest, the residual film can be directly plowed into the soil for degradation without the need for recycling, completely degrading into water, nitrous oxide, and inorganic salts, without polluting the soil.

Good Performance

Good mechanical performance, not easily damaged or broken, can meet the needs of mechanical film laying, and does not wrap around the machine after harvesting.

Personalized Customization

Good mechanical performance, not easily damaged or broken, can meet the needs of mechanical film laying, and does not wrap around the machine after harvesting.